update:2016-07-19 00:00:00

series:300 biomass gas generator set

1.300 series biomass gas engine:

biomass energy resource in china is quite rich, just all kinds of agricultural wastes (such as straw) amount of resources each year quite to 3.08 million tons of standard coal, the amount of fuelwood resources quite to 1.3 billion tons of standard coal, so with the development of modern technology and utilization of biomass and for the establishment of sustainable development of energy system, is of great significance in promoting the economic and social development and ecological environment improvement.

300 series of biomass gas engine, waste rice husk, straw, wood powder, sawdust as raw material, through the gas furnace combustion, fuel, fuel, engine work. such as rice husk, straw, wood powder, sawdust instead of expensive and tight oil resources development and utilization, there is a better comprehensive economic benefits, but also to eliminate a large number of rice husk, straw pollution of the environment.

according to biomass gas combustion characteristics and low heat value (4mj/nm3 left and right) and the high tar characteristics, our company combined with 8300 diesel engine for large diameter, long stroke and other characteristics, and the academy of collaboration with the circulating fluidized bed gasifier technology, the successful development of the type 83 of bio gas engine, the technology reached leading level at home and abroad, and has characteristics of compact structure, simple operation, reasonable arrangement and easy maintenance, etc..

each type of unit is mainly used in land power generation, the frequency can be divided into 50hz, 60hz, can be single unit operation can also be multiple units in parallel operation.

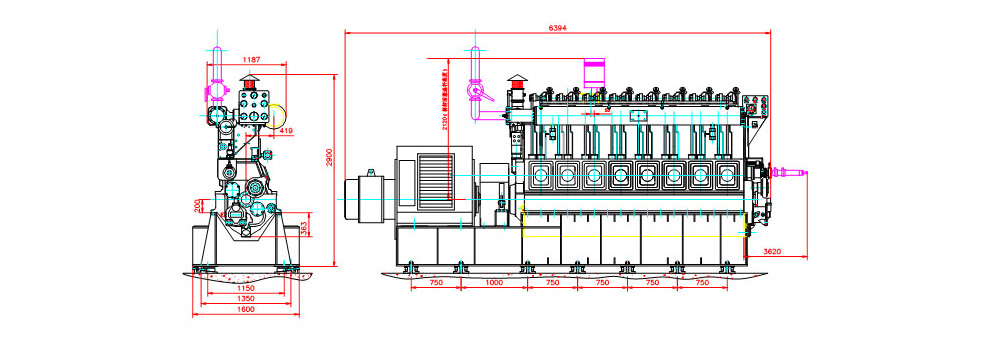

biomass gas generator set outline size chart:

technical characteristics:

(1) the gas mixing device is equipped with a hybrid or electric control mixer, which is equipped with proper timing and proper ignition timing, which is conducive to the full combustion of combustible gas.

(2) a reasonable intake system, so that the air and gas mixture more uniform, more fully combustion, improve the utilization rate of gas, gas inlet pipe at both ends of the installation of explosion-proof door, improve safety.

(3) the air inlet pipe through special design, can reduce the air intake pipe of the condensation of tar, good maintainability, high safety.

(4) the reasonable design of the cam profile, select reasonable, exhaust timing, the inlet and exhaust valve opening time and overlapping angle control within a reasonable range can backfire in the intake pipe of the risk reduction, and to ensure a certain degree of sweep gas, can reduce the exhaust gas temperature.

(5) the exhaust pipe adopts a water cooling structure to reduce the temperature around the generator.

(6) using the american altronic company to produce the ignition system, in order to obtain high ignition energy and precise ignition time, to ensure the safety and reliability of ignition, to meet the needs of the ignition of biomass energy.

major advantages:

(1) power. unit power can reach 450kw, is the current domestic market, the maximum power of more than 2 times, can better meet the needs of large scale power plant.

(2) high reliability. the unit prototype for domestic technology mature 8300 medium speed diesel engine (maximum power of 1103 kw/600rpm) and transformation for gas engine maximum power only reached 600 kw/600rpm and corresponding mechanical load far less than diesel index, therefore the reliability is higher.

(3) the province of material consumption. a 8300 biomass engine in the 400kw load, and two 200kw units in the load (190 190) kw compared to save material about 5%, reducing the cost of electricity, the performance of a good economy.

(4) cylinder exhaust temperature is low, compared with the prior domestic 200 kw units, lower exhaust temperature 60 to 90 deg c, has reached the international advanced level. greatly reduced the engine's heat load, the extension of the valve and other parts of the service life, the overall reliability of the machine has been further enhanced.

conditions of use:

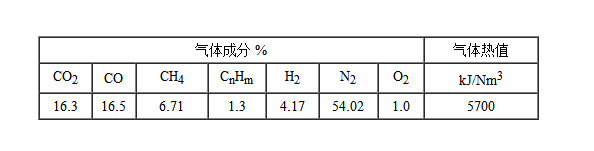

(1) the gas composition and calorific value are as follows:

(2) gas source conditions:

before the use of biomass gas should be properly filtered, gas-liquid separation, pressure, if the temperature is too high, it should be cooling treatment, and to ensure that no liquid in the gas component. pressure change rate is less than or equal to 1kpa/min, tar content is less than or equal to 20mg / nm3, hydrogen volume fraction is less than or equal to 6%, impurity particle size less than or equal to 5 m, moisture content is less than or equal to 20mg / nm3, impurity content is less than or equal to 30mg / nm3.